Good quality is not just about checking boxes and filling out forms. Consider the diverse backgrounds, personalities, and tendencies of the individuals responsible for quality assurance/quality control on your team. 1

A lawyer, a developer, and an engineer walk into a sauna … no, this is not the beginning of a bad joke, it's a story of personality types and how they can affect your quality process. Many (including myself) have written articles about checklists, protocols, and best practices to follow for quality management, but the implementation of all of this depends on your people as individuals beyond their role on the job site.

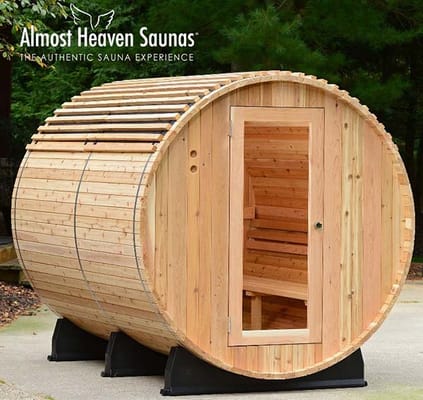

I recently watched three fellows assemble a wood-barrel sauna. The unit came in numerous pieces: 2 large end caps and dozens of individual 4-inch "staves" to be assembled one-by-one and numerous other accessories and details, along with a 10-page instruction manual. Installation looks something like the following.

Once all of the staves are in place around the circumference of the barrel, four large metal bands encircle the barrel and are torqued down to hold the barrel together.

Prior to mobilization, the engineer read the instructions at least three times in detail while staring into the many boxes of materials that came with the kit. He's digested all of the instructions (except for a few, but those will "work themselves out"), he's got a plan, and all he needs is two additional sets of hands to make this project go. The lawyer and the developer show up on site, and immediately the developer (the planner) starts to organize the logistics of the build, looking for efficiencies in the staging and material delivery process (i.e., moving the pieces from the garage to the backyard). He's the dreamer of the group, always coming up with some way to hack the process.

The lawyer comes ready to work and brings a 6-foot level, pun intended. He has a positive, enthusiastic attitude and takes direction well. He's out there to enjoy the day, and get his hands dirty … he lets the engineer and the developer run the show. The engineer directs the work since he's the only one that read the manual, and they begin to build. (Note: These characters in no way are meant to correlate with their professions. Any resemblance between their line of work and their personality is mere coincidence. I simply thought labeling them by occupation was more colorful than calling them Tom, Dick, and Harry).

So, the construction begins. Plastic bases on top of leveling pavers, bottom staves onto plastic bases, vertical end caps onto bottom staves, and then vertical staves nailed into the end caps one by one, building the room from the bottom up.

The engineer followed the directions to a T, except there was one note in the instructions that didn't quite make sense to him: "Be sure to only nail the staves to the end caps halfway up the barrel." Why only halfway up? If some nails are good, more nails are better, right? And aren't we trying to build a really solid final product? Definitely. Pass the nails. The lawyer wasn't quite sure about this, even though he couldn't say WHY they should only nail halfway up, he knew there must've been a reason this note appeared in multiple places (see notes below, highlight added for emphasis).

The lawyer cautioned the other fellows on "overlooking" (read: overthinking) this piece of instruction, but the counselor's objection is overruled. Keep nailing, gents. So, they nail the staves into the end caps all the way up to the top of the barrel. Man, that thing is solid. Nice job. And the following bit of instruction is somewhat confounding as well.

"[T]hose [staves] from approximately the 10 o'clock to 2 o'clock positions are actually spread away from the end sections" … what does that mean? See the following figure.

The next step is to insert the very last stave.

(See Almost Heaven Saunas, which makes delightful barrel saunas to assemble at home, for more diagrams, photos, and videos of the process if you're interested.)

The master plan has just been revealed. One must stop nailing at the halfway point to allow movement among the staves at the top half of the barrel, so that the last stave can be wedged in, creating a buckling gap, which will enable a tight seal when the metal bands are cinched around the barrel. If the staves don't move (because they are nailed in place), there is no gap for the metal bands to close around, and the tightness of the system will be limited by the end caps.

Flexibility was the key; the very movement they were trying to eliminate with more nails was actually the crucial element to ensuring a tight system.

The developer was certain he was bettering the product by using more nails. The engineer wasn't sure about that and the extra spacing issue, but he had read the manual so many times that he deferred the issue, figuring it would work itself out somehow in the field. The attorney had culpability as well, having not voiced his opinion; nevertheless, he did his best to wipe the "I told you so" look off of his face as they deconstructed half the staves, removed the nails, and then reinstalled the staves.

Since the wood was cedar (extremely soft), and the nails were finishing nails, they had to take extra care not to split the staves when hammering the countersunk nails through the back of each stave. This problem was exacerbated by the fact that they had also nailed EVERY stave when the instructions said to nail every two to three staves. (I bet you can guess whose idea that was.) This delicate, selective demolition and rework effort added about an hour to what was otherwise a 3-hour build—a roughly 30 percent increase in the schedule.

This is not the end of the story, though. That additional time was easily offset by the engineer's preplanning efforts (reading the other nine pages of the manual in detail) and the developer's logistics and staging hacks that streamlined the material handling and layout. It took the skills of all three minds to ensure a successful project. The sauna room was built expertly in the end—plumb and secure and with no extra parts.

Apply the Lessons Learned to Construction Quality

Your project teams likely have similarly diverse backgrounds, thought processes, and personality types. It goes without saying that it takes more than a 10-page instruction book and a free afternoon to ensure quality on a large-scale construction project; however, the people dynamics are similar. Does your quality program consider the symbiotic relationship between the program AND the people who implement it? Are you using the strength and diversity of your team to your advantage? Are you capitalizing on their various experiences and perspectives? Are they engaged and invested in the process you've prescribed? Might they have a different approach to share to the betterment of the project and perhaps the overall program?

Quality is everyone's responsibility. In our sauna example, everyone played a role, and all contributed to the success of the project, even with the hiccups that inevitably come along in construction. The result is a well-built product and a happy customer. But, remember, it takes a diverse set of skills, values, and thought processes to bring this concept to reality. It truly takes all kinds.

Opinions expressed in Expert Commentary articles are those of the author and are not necessarily held by the author's employer or IRMI. Expert Commentary articles and other IRMI Online content do not purport to provide legal, accounting, or other professional advice or opinion. If such advice is needed, consult with your attorney, accountant, or other qualified adviser.

Footnotes